NVH Simulation_

NVH, Acoustic & Audio System Simulation

NVH (Noise, Vibration & Harshness) simulations allows OEMs and suppliers to assess the acoustic performance of their products in the early design phases, before prototype parts or vehicles are available. This prevents costly reworks later in the development cycle. Acoustic and Vibration simulations can also be used to optimise design concepts. NVH simulations are also very useful for assessing the effect of proposed mitigation measures which would be challenging to conduct as real-world test cases.

ARC also offer simulation services to support acoustic projects and audio system development.

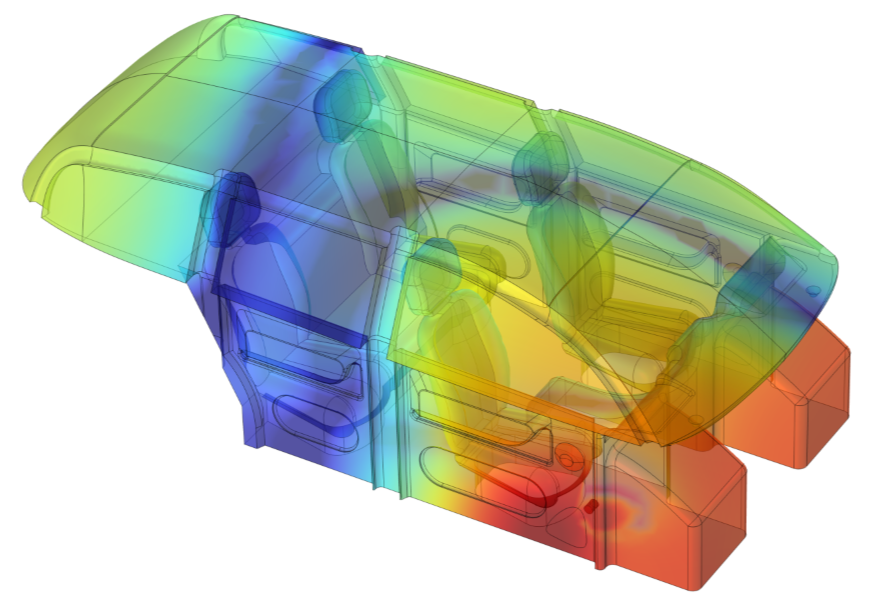

Vehicle Cabin Interior Simulation – Seat Mechatronic Systems

ARC offers NVH (Noise, Vibration & Harshness) Simulation services to our automotive clients. This includes simulations relating to both acoustic and vibration phenomena, as well as coupled-studies, such as structure-borne noise.

Our NVH Simulation services assists clients in ensuring that their products are right-first-time, with reduced prototyping and physical development costs.

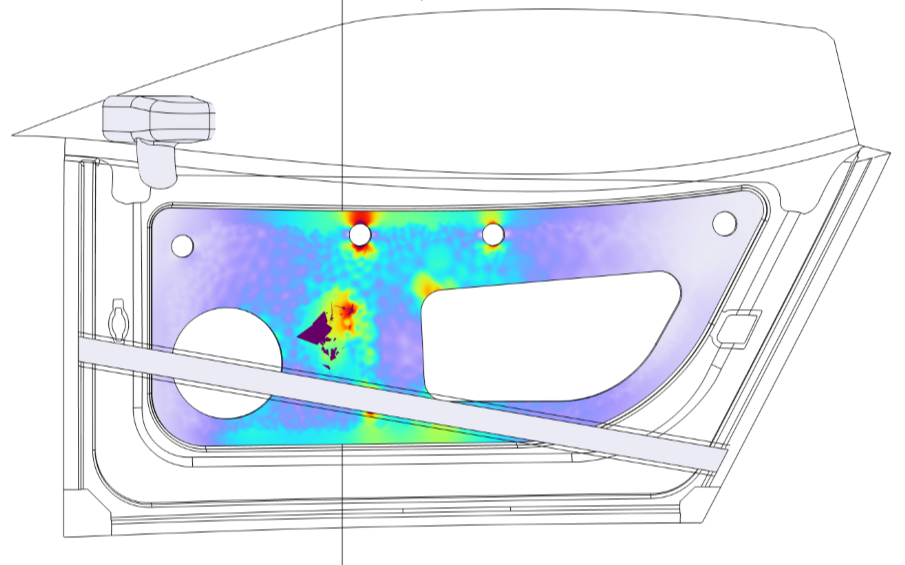

Vehicle Door Vibration & Tactility Simulation

ARC acoustic simulation services are based within the domains of Finite Element Analysis (FEA) and, for high frequency acoustic studies, Raytracing methods. This allows us to provide accurate and reliable acoustic and vibration simulation projects across the complete tactile and auditory frequency range.

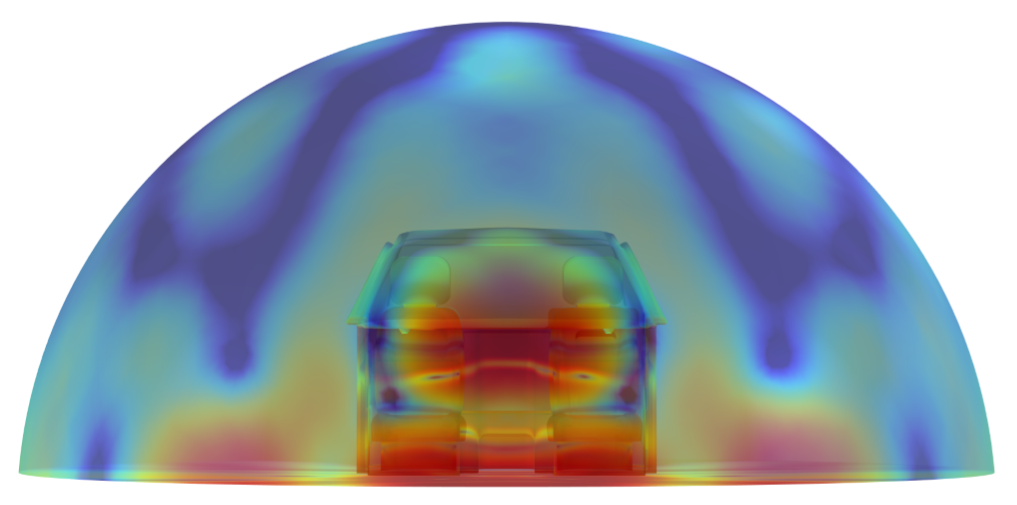

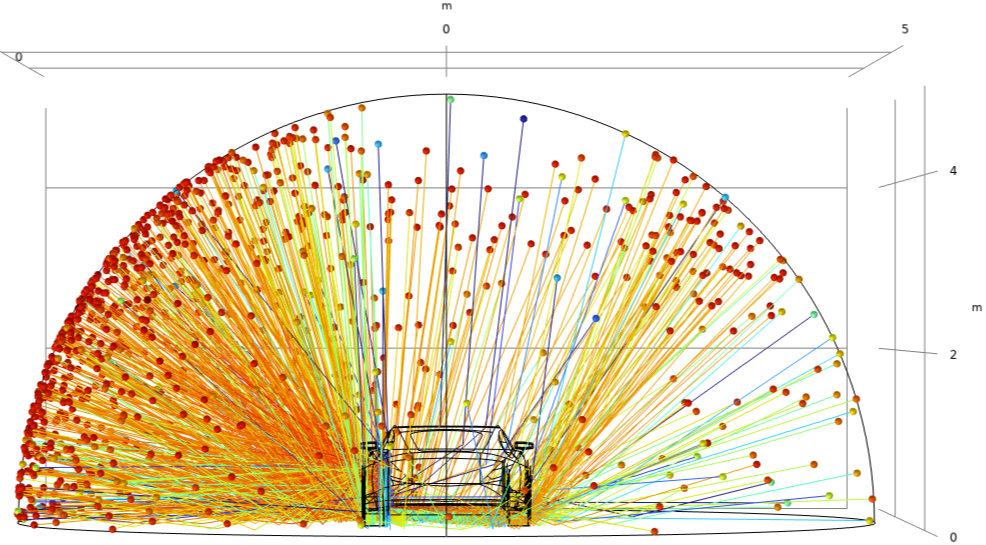

AVAS (Acoustic Vehicle Alerting System) Simulation – FEA Method

ARC NVH simulations can be deployed across several automotive use-cases, a few of which are highlighted below:

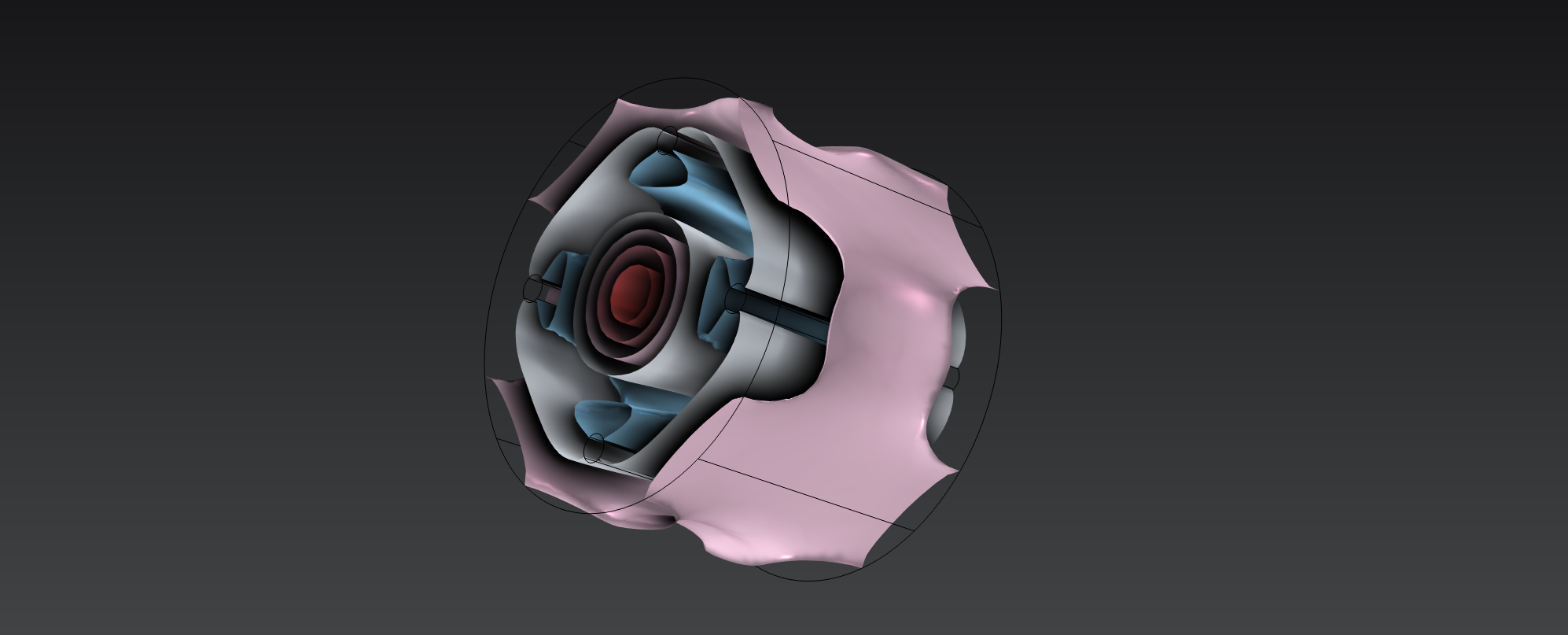

- Noise & Vibration Transfer: eMotors / Drivetrain / Powertrain noise and vibration transfer to cabin occupants or the external environment.

- Operational Sound Quality (OSQ) / Powered Ancillary Systems: NVH optimisation of cabin ancillary devices & HVAC systems.

- Modal Analysis and Structural NVH Simulation: Local Dynamic Stiffness, Modal Response and Optimisation studies.

- Cabin Refinement: Digital prototyping of cabin ancillary systems, such as HVAC acoustics, powered ancillary systems and mechatronics.

- AVAS (Acoustic Vehicle Alerting System) Simulation: Ensuring vehicles can achieve regulatory compliance with external noise level requirements. Development of external loudspeaker mounting strategy and quantity.

- Palliative Assessments: NVH assessment of proposed palliative measures to optimise noise & vibration concerns.

AVAS (Acoustic Vehicle Alerting System) Simulation – Raytracing Method

If you want to learn more about our NVH simulation services, please contact us.